There is a man in my life named Elvis. I’m going to share some facts about Elvis; see if you can guess his job.

About once a year, my family experiences a crisis and we urgently, desperately call Elvis.

Elvis sets his own schedule and rates (which have increased with time).

Elvis is not a rockstar in the same sense as his namesake, but he is a rockstar in the sense that when he arrives, my family cheers.

Elvis is a plumber.

Along with what’s listed above, here are some other facts about Elvis’ profession, and other skilled trades:

There is a shortage of skilled tradespeople — like plumbers, electricians, and welders — and this shortage is expected to grow as more Baby Boomers retire.

Because of this shortage, salaries in the skilled trades have risen significantly in recent years. The median pay for new construction hires rose 5.1% to $48,089 last year, compared to $39,520 for new hires in professional services. This is the fourth year that median annual pay for construction hires has superseded that of new hires in the professional services and information sectors (like accountants or IT maintenance workers).

As a result, many young people are now enrolling in vocational training programs instead of college. Last year, the number of students enrolled in vocational-focused community colleges rose 16%, while overall enrollment in community colleges and four-year colleges has declined.

Unlike young college grads, who face the worst entry-level job market in years (a phenomenon I wrote about last week), these students face no shortage of job offers. One of my favorite quotes from a 17 year old welding student: “It honestly feels like I’m an athlete getting all this attention from all these pro teams.”

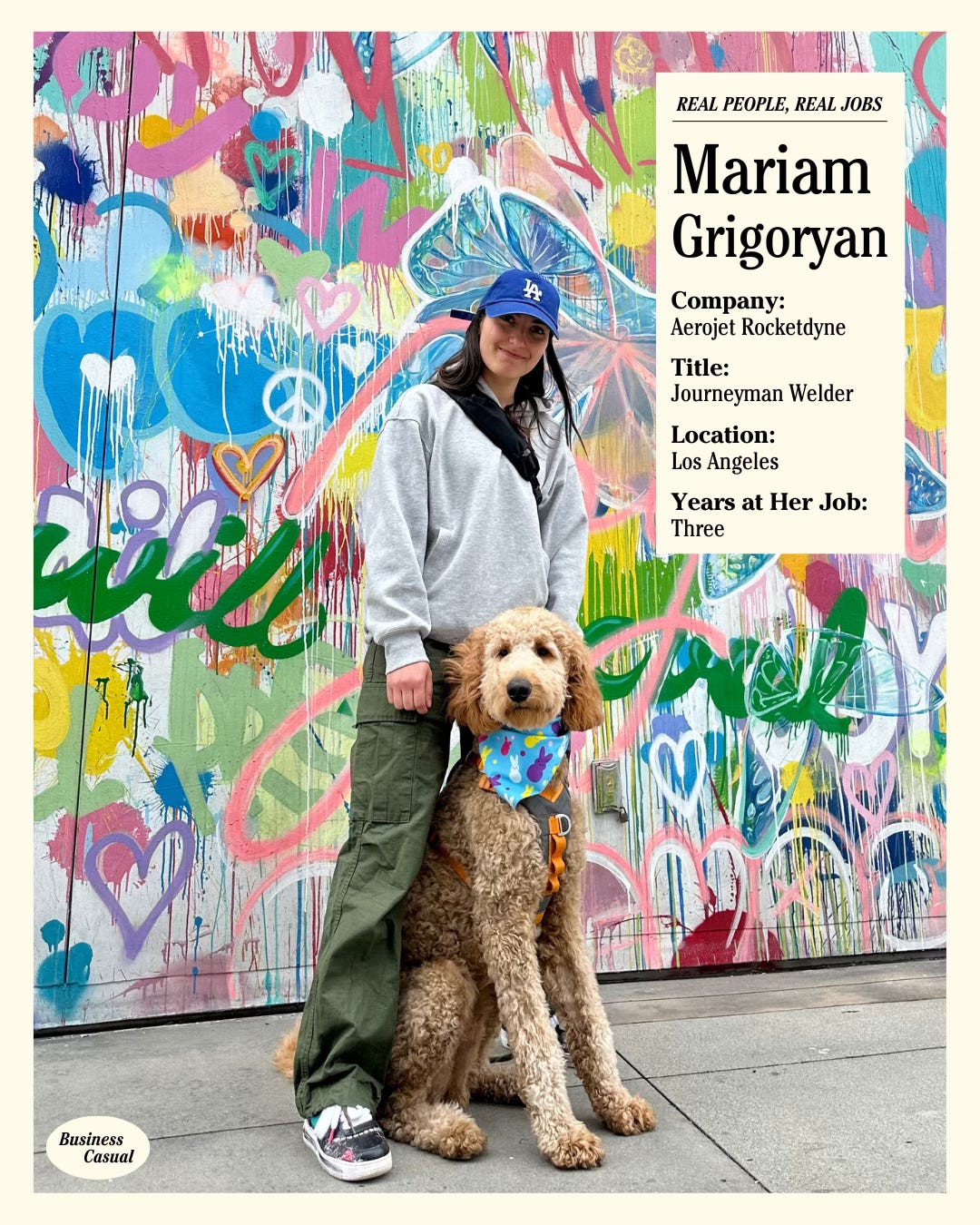

Given how much I’ve read about this new “toolbelt generation,” I wanted to speak with a real young person who’s chosen this path for Real People, Real Jobs. Here’s what she had to say about forgoing a desk job for a hands-on, skilled trade offering a lot of professional opportunity.

Mariam Grigoryan is a welder in the aerospace industry, currently working at Aerojet Rocketdyne, one of the leading aerospace manufacturers in the US. Mariam initially planned to become a mechanical engineer, before a welding course at a local community college had her “hooked” and changed her entire career trajectory. Here’s what it’s like to be in the (growing!) minority of Gen Zers working in a skilled trade.

One thing I love about my job is that it is diverse and if you’re good, many will hire you.

On a workday in her life: Tuesday, May 13, 2025

I’ll usually wake up around 8:00/9:00 am, but this morning my body chose to wake up at 7:00 am. Taking advantage of this rare burst of energy, I got to spend time with my boyfriend. We walked Hudson, our dog, before he went off to work. I brush Hudson for as long as he will let me, then I have breakfast. I have a cup of coffee and some french toast while I watch an episode of One Piece. After breakfast I go to Costco to grab some household essentials, like snacks, and then back home to make lunch. I meal-prep some food, bake some bread, then shower and get ready for work. Before heading out I feed Hudson one more time and take him on a quick walk. I live 10 minutes away from my job and I always push my time limit. Today I am working second shift, so my official start time is 3:18 pm, which is exactly when I get there, and ends at 12:48 am. I’ll drive home for my lunch breaks and enjoy the small amount of time I have with my boyfriend during the week, then go back to work and come home around 1:00am, and get ready for bed to do it all over again.

On a misconception people often hold about her job:

Many believe that this is a labor intensive job, and it can be, but I am a TIG (Tungsten Inert Gas) welder. Depending on where you go with it, TIG welding is described as a “precision welding technique” or as I call it, a “fun desk job.” Starting off in my career, I walked into my booth (the equivalent of a cubical), and sat on a bench (the equivalent of a desk) to weld parts. Aside from all the proper protective equipment, it really does feel like arts and crafts with molten metal at a desk.

On something about her role that you wouldn’t know from the job description:

There are many levels of welding and different types so you never stop learning. Fabrication also goes hand-in-hand with welding. At certain aerospace jobs they prohibit you from fabricating anything because there are people who do that specifically, so teamwork is a big thing. But at mom and pop shops, you have to know how to fit things up to give you the best outcome. A good weld is 90% fit/set up and cleanliness, the actual welding is 10%.

On what someone who wants her job can do right now to get there:

Enroll in a welding class! It’s so easy to do and fun. I started at Glendale Community College, they now have an introductory class with VR welding so you can see if it’s something for you without getting “dirty.” In Los Angeles, College of the Canyons also has incredible courses (take Andres Carillo’s class). I went through all the welding classes so that took me a year, but I only took one semester of the TIG welding course and got my certification for welding steel. It was the first step towards finding a job.

On her favorite part of her job:

The things I weld, as simple as that sounds. At my current job we build rocket engines! It doesn’t get cooler than that. Just the incredible thought that the work I’m doing will take people to the moon! We are building the RS-25 engines for the Artemis missions.

On the most challenging part of her job:

Some of the work is difficult; I’ve squeezed myself into the smallest places to weld something. It’s demanding on your body from time to time, but staying active and moving is so important to me so this works for me. The more critical hardware gets, the more paperwork follows it, so fully understanding the drawings (blueprints) and requirements of the work that needs to be performed can get confusing.

On forgoing a desk job for a skilled trade:

I think a trade job like the one I’m doing keeps me active and aware of my abilities. I’m sure it’s not the case for most, but my ADHD personality wouldn’t last very long at a desk job. I have been incredibly lucky with the support I’ve gotten when I chose to take on welding as a career. There are always the non-believers that say “you won’t last” or “you aren’t good enough,” but those people are really easy to block out because I always want to move forward. I’ve taken chances and put myself out there to get to better places. I’m not saying I’m the best, there’s still a lifetime of information and skill to be learned, but I’ve continued to move forward.

It also makes me happy that more people are taking an interest in trade jobs. With the advancement of technology, trade jobs have become more involved and safer. There is automated welding that requires skilled operators. It scratches the intellectual itch of programming and operating and also the instant gratification of seeing your work come out so beautifully.

I am happy with my job and my friends are happy with theirs. We each found careers that fall within our “stress threshold,” so I can’t say that trade work is better than a desk job, a nurse, an engineer, a Tech Specialist, and so on.

In the workplace, my gender has never bothered me or the men around me [editor’s note: women make up only 5% of the American welding workforce]. Yeah some get awkward, but the majority of men are very respectful and haven’t made me feel like an outcast. They haven’t belittled my intelligence or skill, they offer help because we are a team and lookout for each other, and it’s respect all around. It has the same feeling as a bunch of children running around a playground at recess.

On the different types of jobs and paths available to her as a welder:

One thing I love about my job is that it is diverse and if you’re good, many will hire you. TIG welding is my specialty so I would be able to go from aerospace, to automotive, to general manufacturing. This kind of job is needed everywhere you go. If money is the driving factor then I would say working for a city government is where you would get the most money and best benefits.

One thing (tool, skill, secret, etc.) anyone who wants her job must know:

Do research! Like I’ve said, there is so much information about welding and materials that can make you great. Understanding what you are working with is important.

One person or publication you must follow if you want her job:

The best I could say is start with one welding video on Youtube and fall into the rabbit hole. Weld [HAGOJIBI] on Youtube is a good place to start. He is a sweet Korean man who breaks down so much information in little to no words.

Her work-life balance on a scale of 1 to 10 (1 = works all the time, including weekends, and doesn’t have any personal free time; 10 = standard 9-5 job with manageable demands):

If I choose not to work overtime then it’s an 8. But working second shift (3:18 pm-12:48) can mess with seeing friends and family during the week. If I work overtime then it can become a 1. Being a union employee, we have strict working hours, and many companies make overtime a requirement, but you will get paid accordingly. At my current job they ask, but don’t enforce it, so I have time to enjoy my hobbies and see loved ones.

Thanks for reading! Share this post with anyone you know who’s tired of sitting behind a desk. And if you’re a Gen Zer interested in a career in the skilled trades, I’d love to hear from you. Reply to this email or DM me on Substack.